ISPM 15 Standard: an imperative for sustainability and international export

Do you need boxes for the safe transport and export of industrial products?

Our design office provides tailor-made solutions, whatever your sector: chemicals, metallurgy, defence and armament, mechanical engineering, and more.

Our folding plywood boxes can be shipped anywhere in the world thanks to their reliability and full compliance with the ISPM 15 standard.

But what exactly does this standard mean? Here are the topics covered on this page:

- ISPM 15 certification explained

- The different wood treatments, exemptions, and marking requirements

- ISPM 15: an imperative for environmental protection… and for customs clearance

- Other questions about ISPM 15? We have the answers!

Certification

The International Standard for Phytosanitary Measures No. 15 – ISPM 15 – aims to reduce the spread of harmful organisms that affect plants. This phenomenon is mainly caused by the transport of wood-based packaging, particularly in the context of exports. ISPM 15 was adopted by the FAO (Food and Agriculture Organization of the United Nations) as part of the International Plant Protection Convention (IPPC). It is defined by the Regulation of Wood Packaging Material in International Trade (2018).

First adopted in March 2002 and subsequently revised on several occasions, its purpose is to harmonise measures to prevent the infestation of an importing country’s forests by pests contained in wooden packaging. The wood is therefore treated to minimise the risks of introducing or spreading diseases and insects that could negatively affect plants and ecosystems.

The different wood treatments, the exemptions and the marking

Since 2018, two types of treatment have been approved for wood packaging materials:

-

debarked wood then treated with methyl bromide and sulphuryl fluoride;

-

debarked wood with heat treatment applied either before or after debarking.

In terms of packaging, several items may be exempted from the ISPM 15 standard, and in the case of wooden boxes, this applies to:

-

packaging materials made entirely of thin wood (6 mm thick or less);

-

packaging materials made entirely of processed wood material, such as plywood, particle board, oriented strand board or veneer that has been produced using glue, heat, pressure, or a combination of these techniques.

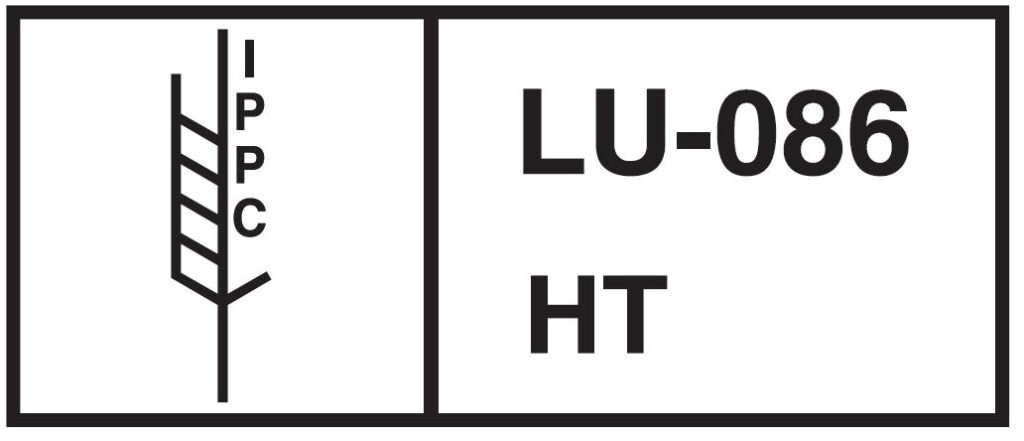

When it comes to marking, NO-NAIL BOXES strictly complies with the required elements: the symbol, country code, producer/company code responsible for applying the treatment, as well as the treatment code according to the methods used.

The characters used and the position of the mark may vary, but the size must be sufficient for the marking to be visible and legible without visual aid. The mark must be enclosed in a rectangle or a square with a vertical line separating the symbol from the code elements.

An imperative for environmental protection…

and for customs!

Treatments help prevent the spread of insects such as the pinewood nematode – a worm that attacks pine – or the Asian longhorn beetle, which can damage several species of hardwood. Today, this export directive applies to the majority of countries, nearly 80 across all continents.

Beyond the environmental responsibility it entails, compliance with the ISPM 15 standard ensures that your clients receive their products while avoiding, as much as possible, delays, blockages, and even the return of your goods – however strategic they may be.

This is why we are fully committed to the strict respect of this essential standard, every day and at your side! Customer satisfaction is our priority, and we will soon return to the concrete advantages of complying with this virtually indispensable standard.

FAQ

-

Compliance with the ISPM 15 standard allows companies to ensure that their shipments pass customs controls more smoothly, reducing the risk of delays and unforeseen costs. By remaining compliant, exporters avoid sanctions and safeguard their reputation with international partners.

-

To find out whether a country applies the ISPM 15 standard, it is recommended to consult the official customs websites of the importing country or international export guides. Professional organisations and chambers of commerce can also provide up-to-date information on phytosanitary regulations.

-

Heat treatment raises the wood to a high temperature in order to eliminate pests, without leaving any residues. This makes it suitable for food products and more environmentally friendly. Chemical treatment, such as fumigation, uses gases to kill pests. It is fast, but may leave residues, which can create constraints for certain goods and is less eco-friendly.

-

The validity of the ISPM 15 treatment depends on the proper management of the storage conditions of the wooden packaging. As long as the packaging remains intact and is stored correctly, protected from pests, the treatment remains valid. However, treated wood that is damaged or exposed to pests may require re-treatment.

-

No, although the standard is mainly applied to exports, some countries also impose ISPM 15 for domestic trade, particularly when goods are transported between different regions or islands. It is important to check the specific regulations of each country.

-

The ISPM 15 standard evolves to adapt to new phytosanitary threats identified by international experts. Revisions make it possible to adjust treatment methods or modify marking requirements in line with new scientific findings, thereby ensuring continuous protection against pests.

-

In the event of non-compliance, companies may face customs blockages, fines, or even the destruction of goods at the sender’s expense. This can lead to significant financial losses, not to mention the impact on the company’s reputation and business relationships.

-

Les traitements NIMP15, qu’ils soient thermiques ou chimiques, visent principalement à éliminer les nuisibles et ne modifient pas significativement la résistance mécanique du bois. Cependant, le choix du traitement peut influencer son apparence. Le traitement thermique, par exemple, peut foncer légèrement le bois sans en altérer la qualité.

-

Does the treatment of wooden packaging according to the ISPM 15 standard affect wood quality? 1. Reduced risk of blockages and returns Boxes compliant with the ISPM 15 standard minimise the risk of goods being blocked or returned at borders, thereby avoiding significant costs. 2. Simplified customs formalities ISPM 15 boxes make customs procedures easier, saving time and reducing delivery delays. 3. Lower phytosanitary inspection costs ISPM 15 certified boxes reduce the need for additional checks, helping to limit the costs associated with such inspections.

-

The ISPM 15 standard is required for the majority of exports to countries that apply this regulation, particularly in North America, Asia and Europe. However, some countries may have specific requirements or different tolerances regarding treatments and markings. This is why it is always advisable to check the regulations of each destination country before shipping. NO-NAIL BOXES supports its clients in this process to ensure that every shipment complies with both local and international rules.

-

ISPM 15 boxes, by ensuring the absence of pests in packaging, prevent the spread of harmful organisms and thus protect local ecosystems. This helps to avoid biological invasions that could cause significant environmental damage. In addition to this ecological aspect, treated wooden boxes are often reusable and recyclable, which reduces the need for new raw materials and contributes to a more sustainable supply chain.

-

NO-NAIL BOXES provides a personalised advisory service to help your company choose the ISPM 15 compliant box best suited to your needs. Our experts take into account the specific characteristics of each product, the mode of transport (sea, air, road), as well as the regulations of the destination country. We offer tailor-made boxes that optimise loading space and reduce transport costs, while ensuring full compliance with the ISPM 15 standard.

-

ISPM 15 boxes are particularly suitable for the transport of high-value industrial products, such as mechanical parts, electronic equipment and chemical products. These goods benefit not only from the protection provided by pest-treated boxes, but also from the robustness of NO-NAIL BOXES packaging, which safeguards them against shocks and temperature variations during transport. In addition, wooden boxes treated in accordance with the ISPM 15 standard are also ideal for products requiring special protection against contaminants.

-

If damage occurs before shipping, it is crucial to ensure that both the integrity of the box and the ISPM 15 marking remain valid. If the marking is altered, or if the box shows cracks that could allow pests to re-enter, it is recommended to replace it or have it re-treated to guarantee compliance. NO-NAIL BOXES can provide assistance with the rapid replacement of boxes and ensure that the new boxes meet ISPM 15 requirements.

-

Yes, the ISPM 15 standard is regularly revised to integrate new knowledge on phytosanitary risks and best treatment practices. Updates may include changes to the types of treatments accepted or to marking requirements. NO-NAIL BOXES closely monitors these developments to ensure its products remain up to date and compliant, thereby guaranteeing clients full conformity with the latest international requirements.

- The importance of ISPM 15 wooden boxes in international trade

- The ISPM 15 compliant box solution by NO-NAIL BOXES for secure international transport