Made-to-measure design

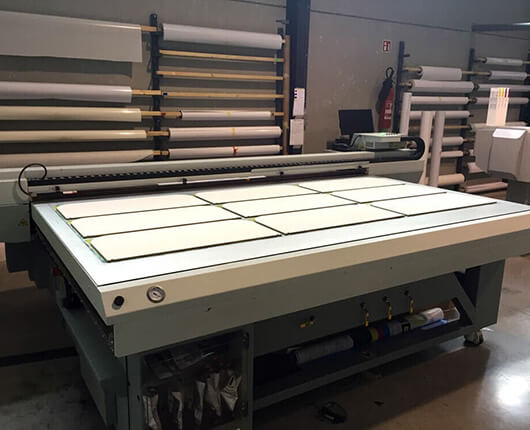

Design office

Our technical department develops custom packaging solutions tailored to the specific requirements of each client. We start with a detailed analysis of the specifications to define the necessary protections against shocks, vibrations, and humidity.

Depending on the complexity of the project, we use 3D modeling tools to design optimized prototypes. Our packaging is tested to ensure its performance and meets quality standards. In addition, we prioritize eco-friendly materials and optimize our designs to minimize our environmental impact.

This approach allows us to meet your protection, transport, and storage needs while reducing your carbon footprint with eco-designed solutions.

Research & development

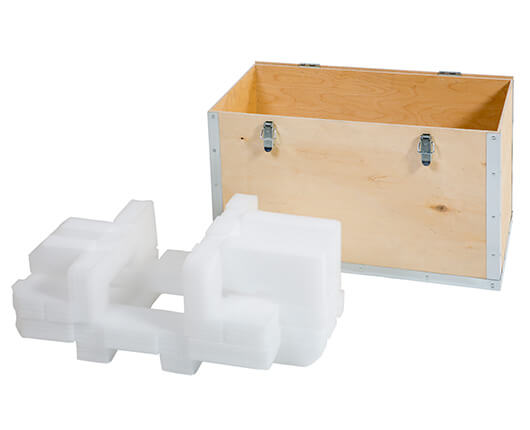

NO-NAIL BOXES continuously invests in Research and Development to design packaging solutions that combine performance and environmental respect.

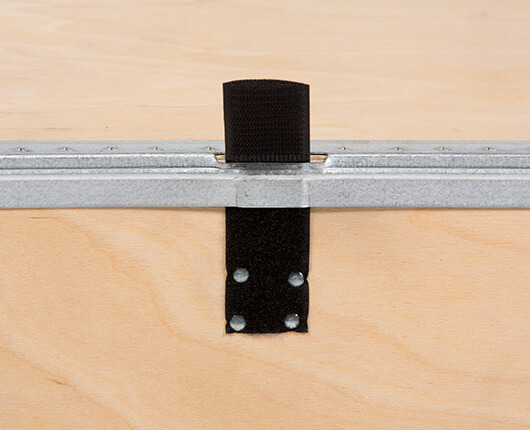

Our technical team focuses on material optimization, aiming to reduce the weight of the boxes, decrease the use of non-recyclable foam, and explore innovative new materials. Our goal is to create robust technical packaging that minimizes environmental impact without compromising quality.

Every day, we help our clients identify potential savings and improve their carbon footprint while ensuring maximum efficiency in the transport and protection of their products.